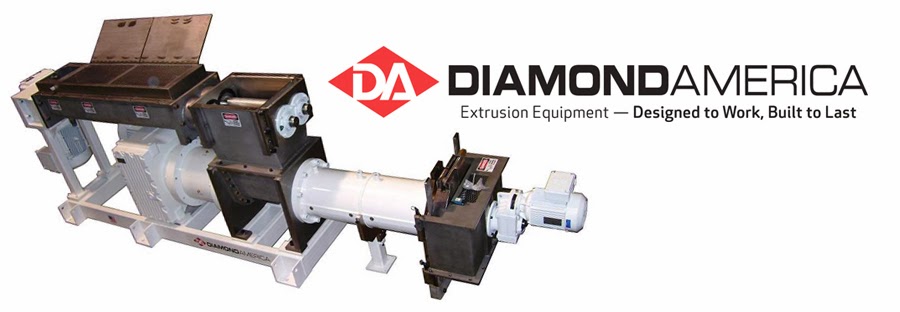

Diamond America

Corporation will introduce the swing bolt configuration, its latest extruder

design feature, at ChemShow 2013, December 10-12 in New York City. The swing

bolt allows Diamond America’s Table Top Extruders to be easily cleaned and maintained.

The unit can be quickly disassembled, the screw and barrel purged and cleaned,

and the die replaced within minutes. As a result, the machine’s downtime is

greatly reduced and productivity is increased.

Diamond America’s Table

Top Extruders (TT Series) are suited for research, testing, quality control,

and production applications, and the swing bolt configuration makes them ideal

for laboratory use when testing different materials or profiles. The TT Series

features a modular design and all units are available with mobile cart to

provide you with ultimate flexibility.

Diamond America offers

both standard 1” and 2” Table Top Extruders and custom designed and built

extruders for special applications such as high temperature or corrosive

polymer processing. The TT Series is currently used by manufacturers to test a

wide range of products and as a teaching tool in research labs in many

Universities and Colleges. “We bought the TT100 extruder manufactured by

Diamond America in order to produce the extruded pellets of molecular

sieves including aluminosilicates and titanosilicates in our lab … the

equipment has been working well on the forming of inorganic

materials,” stated Lan Wu, Technician, University of Alberta.

The TT100 1” Single

Screw Extruder and TF200 2” Twin Feed Extruder with swing bolt configuration

will be on display in the Diamond America booth for all ChemShow 2013 visitors

to see. Details on all Diamond America TT Series extruders can be found at

http://www.daextrusion.com/products/extruders/tt100-extruder/